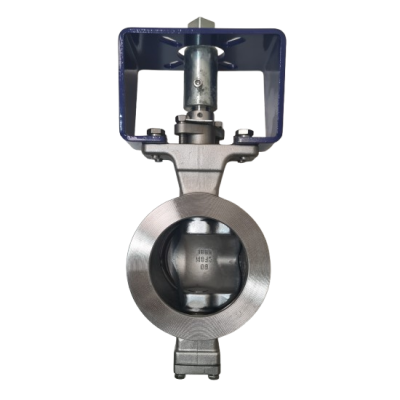

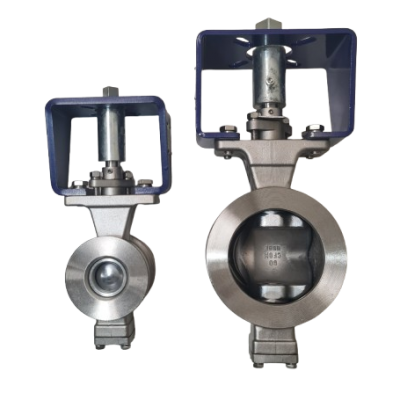

Wafer Type Segment Ball Valve

The Wafer Type Segment Ball Valve offers efficient flow control and tight sealing in a compact design, making it ideal for space-constrained installations. This valve features a unique segment ball design that facilitates smooth throttling and excellent flow regulation in various applications, including water treatment, chemical processing, and HVAC systems. Its lightweight construction and wafer-style mounting enable easy installation between flanges, ensuring reliable performance without the need for additional support. Durable and efficient, the Wafer Type Segment Ball Valve is essential for optimizing fluid control in demanding industrial environments.

General Technical Data

Design standard

Wall thickness standard

Thread standard

Pressures Range

Size Range

Body Material

Face To Face

Flanged RF, FF, RTJ Ends

Butt-Weld BW Ends

Socket-Weld SW Ends

Working Temperature

Testing standard

ANSI B16.34, API 608

ANSI B16.34, EN12516-3

ANSI B1.20.1; BS21; DIN 2999/259; ISO 228-1; ISO7/1; JIS B0203

ANSI 150lb ~ANSI 300lb, PN16~PN64,JIS-10K 1000-2000PSI

DN8(1/4″) ~DN150 (6″)

Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, etc

ANSI B16.10; DIN3202 F1, F4/F5; JIS B2002

ASME B16.5 CLASS 150/300; EN1092-1; HG20592 PN10-PN40; JIS B2238 10K/20K

ASME B16.25, ISO1127/EN12627

ANSI B1.20.1; BS21; DIN2999/259; ISO228/1; ISO7/1; JIS B0203

-196℃~300+℃

API 598; EN 12266

General Design Features

Construction

Port

Ball Type

Stem

Seat Sealing

Fire Safety

Other Design

Three Pieces Body, Two Pieces Body, One Piece Body

Full Bore, Reduced Bore, V-Port, Two-Way, Three-Way, Multi-Port Way

Floating Ball, Fixed Ball-Shaped Ball Valve, The 3-Way Ball Valve

Blowout-Proof Stem

Integral Body Seat, Seat Welded and Overlaid

API 607 4th Edition, BS 5351

Anti-Static Design, Automatic Pressure Relief Design, Emergency Grease Injection Design, Drain Valve, Anti-Corrosion Design, Anti-Sulphur Design, etc