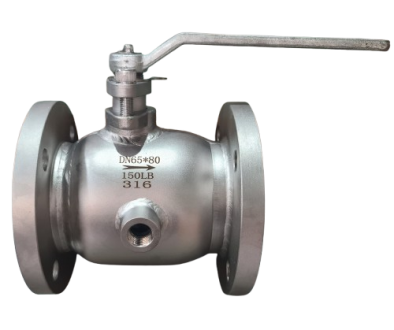

3-PC Body Ball Valve 1000 PSI W.O.G (PN20/32)

A ball valve is a quarter-turn valve that uses a spherical disc (ball) with a hole through the centre to control the flow of fluids. When the valve is open, the hole aligns with the flow path, allowing fluids to pass through. When turned 90 degrees, the ball blocks the flow completely. Known for their durability, tight sealing, and reliability, ball valves are widely used in various industries, including oil and gas, chemical processing, and water treatment. They are ideal for applications requiring a quick shutoff, high pressure resistance, and minimal leakage.

Product Catalogue(s)

General Technical Data

Design standard

Wall thickness standard

Thread standard

Pressures Range

Size Range

Body Material

Face To Face

Flanged RF, FF, RTJ Ends

Butt-Weld BW Ends

Socket-Weld SW Ends

Working Temperature

Testing standard

ANSI B16.34, API 608

ANSI B16.34, EN12516-3

ANSI B1.20.1; BS21; DIN 2999/259; ISO 228-1; ISO7/1; JIS B0203

ANSI 150lb ~ANSI 300lb, PN16~PN64,JIS-10K 1000-2000PSI

DN8(1/4″) ~DN150 (6″)

Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, etc

ANSI B16.10; DIN3202 F1, F4/F5; JIS B2002

ASME B16.5 CLASS 150/300; EN1092-1; HG20592 PN10-PN40; JIS B2238 10K/20K

ASME B16.25, ISO1127/EN12627

ANSI B1.20.1; BS21; DIN2999/259; ISO228/1; ISO7/1; JIS B0203

-196℃~300+℃

API 598; EN 12266

General Design Features

Construction

Port

Ball Type

Stem

Seat Sealing

Fire Safety

Other Design

Three Pieces Body, Two Pieces Body, One Piece Body

Full Bore, Reduced Bore, V-Port, Two-Way, Three-Way, Multi-Port Way

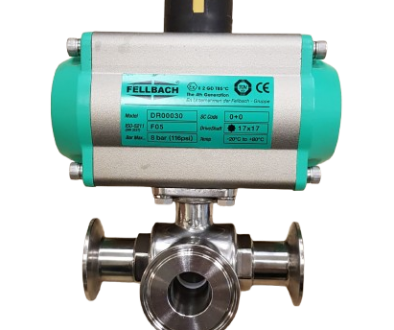

Floating Ball, Fixed Ball-Shaped Ball Valve, The 3-Way Ball Valve

Blowout-Proof Stem

Integral Body Seat, Seat Welded and Overlaid

API 607 4th Edition, BS 5351

Anti-Static Design, Automatic Pressure Relief Design, Emergency Grease Injection Design, Drain Valve, Anti-Corrosion Design, Anti-Sulphur Design, etc