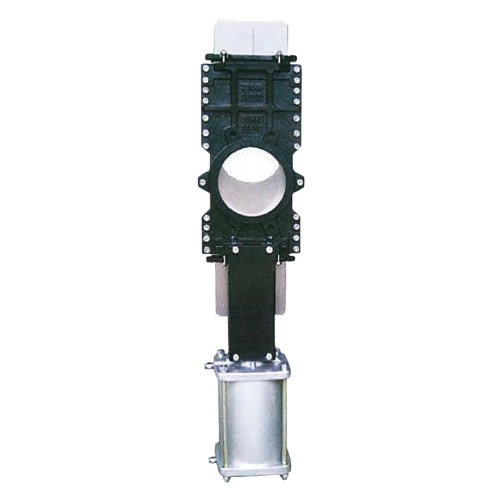

Knife Gate Valve

At WOGS, we offer a robust selection of knife gate valves engineered for reliable shutoff in challenging flow conditions, including slurries, powders, and thick viscous media. Known for their ability to cut through suspended solids and fibrous materials, knife gate valves are widely used in mining, pulp and paper, wastewater treatment, chemical processing, and bulk material handling industries.

Knife gate valves are ideal for low-pressure systems where a compact, unidirectional valve can provide full-flow passage with minimal clogging and wear. Their slim design, easy maintenance, and cost-effectiveness make them a preferred choice for isolation in systems where standard valves may fail.

What Is a Knife Gate Valve?

A knife gate valve features a sharp-edged blade or “knife” that slides through the flow stream to cut and isolate thick fluids or solid-laden media. When open, the gate retracts fully out of the flow path, providing unobstructed flow and low pressure drop. When closed, it seals against the seat to provide tight shutoff, especially in abrasive or slurry service.

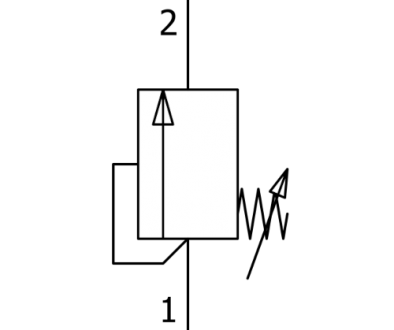

These valves are typically operated manually, pneumatically, or electrically, and are especially effective in applications that require zero clogging, easy cleaning, and maintenance-friendly design.

Types of Knife Gate Valves We Offer:

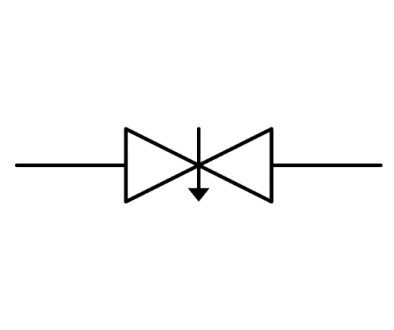

Standard Knife Gate Valves – Designed for general-purpose slurry and wastewater applications

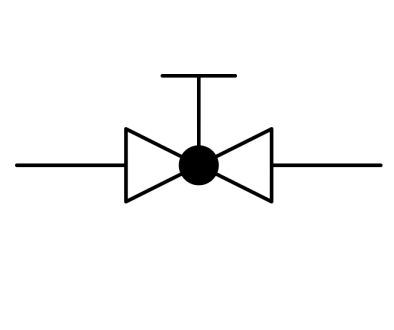

Bi-Directional Knife Gate Valves – Seals in both directions, ideal for systems with reversing flow

Lug and Wafer Type Knife Gate Valves – For versatile installation between flanges

Through-Gate / O-Port Knife Gate Valves – Prevents accumulation and clogging in high-solid applications

High-Performance Knife Gate Valves – Built for corrosive, abrasive, or high-temperature environments